Firbimatic Spa was founded back in 1971 by Gino Biagi, at that time a young entrepreneur with a great industrial vision. Today, 50 years after its founding, Firbimatic holds a position of absolute prominence in the international panorama of manufacturers of solvent and water-based metal washing equipment and detergent.

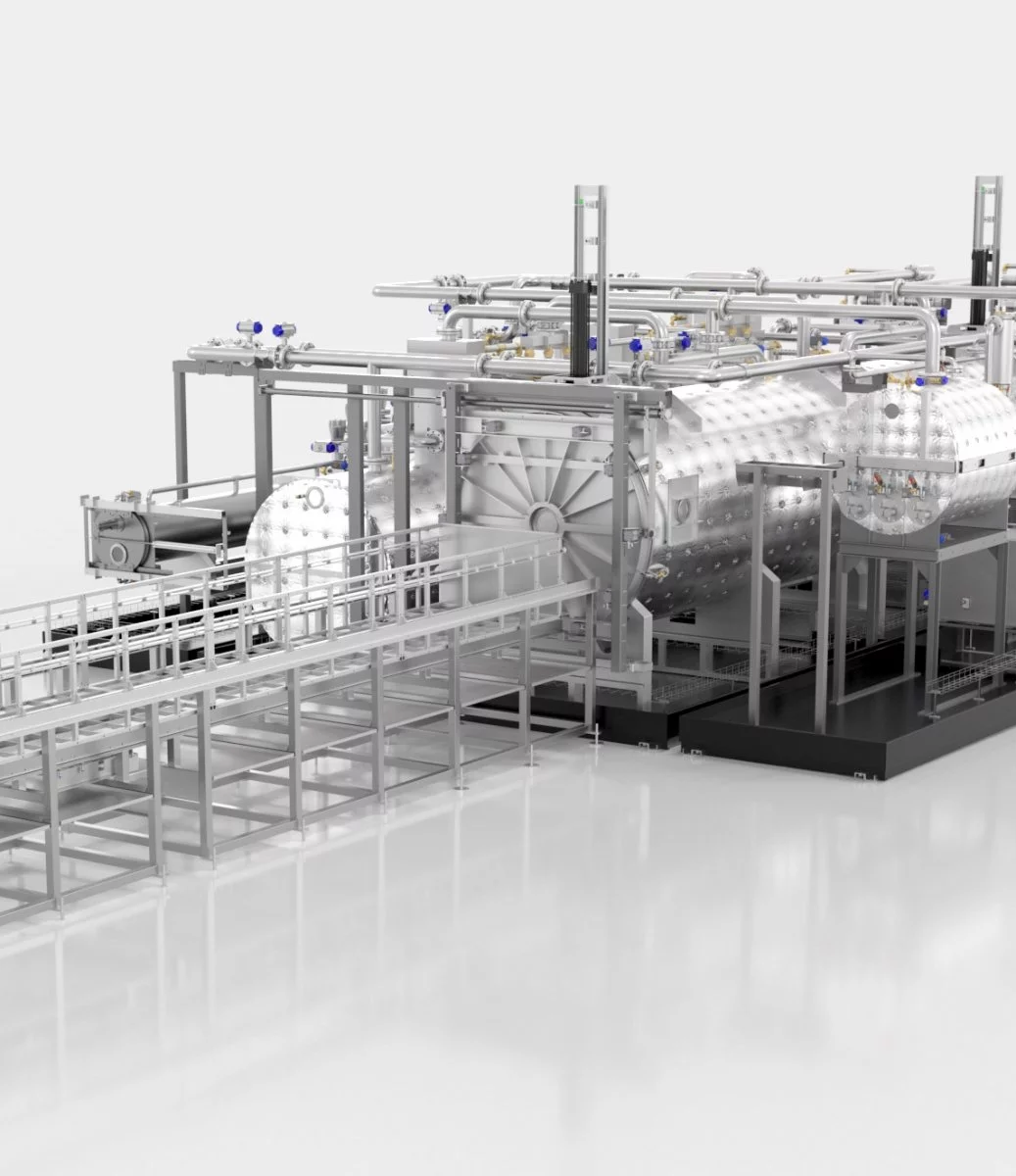

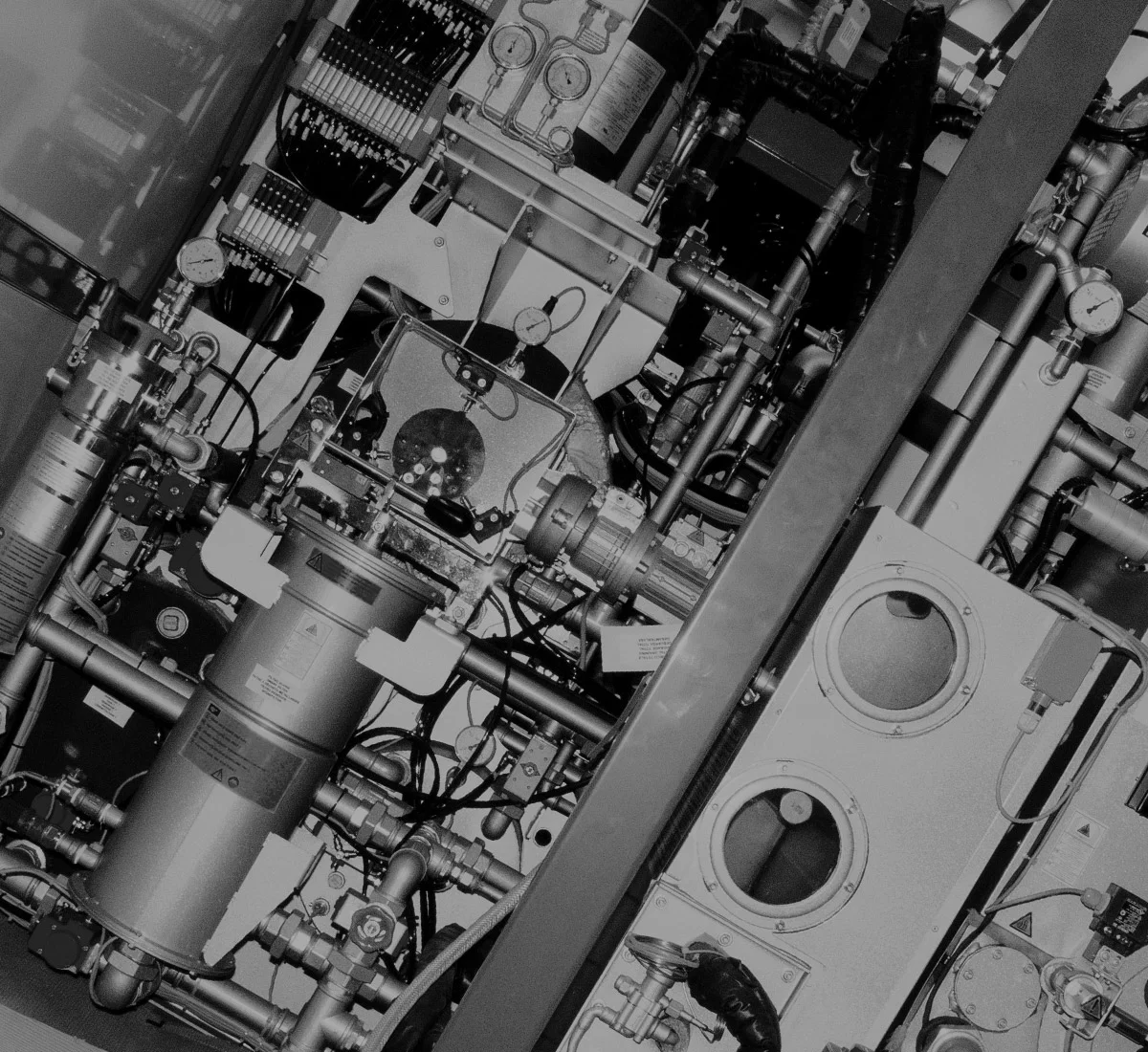

Metal washing machines produced by Firbimatic are widely used by manufacturing, automotive, aerospace, medical and precision engineering companies to remove all organic and inorganic contaminants from their manufactured components.

In order to bring a high-quality industrial product to the market, it is necessary that every step in the industrial processing chain be characterized by a perfect degree of cleanliness. For this reason, Firbimatic offers a wide range of washing systems that enable it to meet the needs of the ever-changing target market.

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.