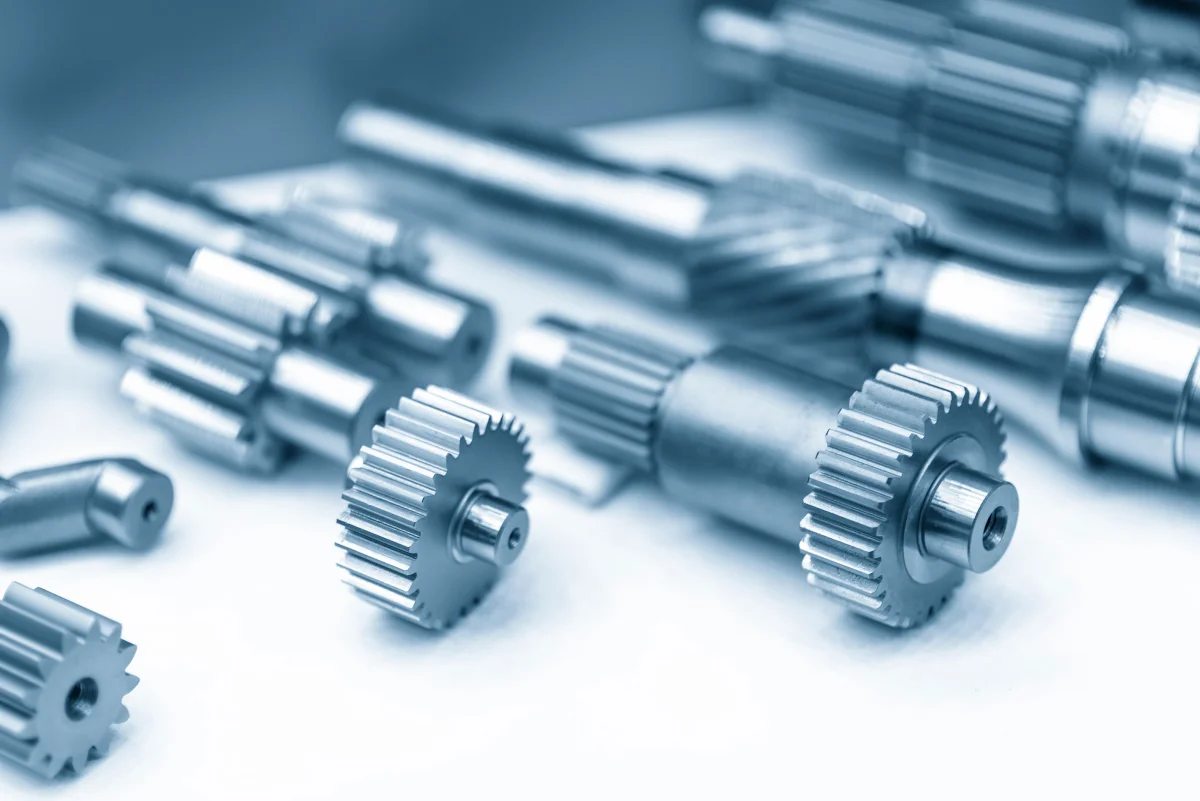

In the industrial context, the correct drying of metal components is a crucial step to ensure quality and precision in the production process.

Drying systems play a fundamental role in this process, and choosing the right method can make a difference in the final quality of the products.

In this article, we will explore drying methods, focusing on their implementation in the industrial setting, with particular attention to the solutions provided by Firbimatic.

1. Vacuum drying system:

Vacuum drying technology is widely used in both solvent and water-based cleaning systems.

The metal components are inserted into the treatment chamber, where the pressure reduced to 1-2 mBar decreases the boiling temperature of the solvent, allowing complete and fast evaporation. Firbimatic, in particular, uses this method in its hermetic circuit systems, guaranteeing a completely vacuum cleaning cycle for an optimal result without emissions into the environment

2. Condensation drying:

The condensation drying method uses heat pumps to achieve fast drying times and low energy consumption. Extremely dry, unsaturated air is blown over the components through a closed loop, quickly eliminating the liquid. The cooled air is then reheated to the desired temperature, completing the cycle. This method can also be implemented in subsequent processes through a separate module or used to cool components.

3. Recirculated hot air drying:

Forced air drying uses hot air to accelerate the evaporation of liquid from the surface of metal components.

This method requires several minutes for complete drying due to the high water content, especially when the parts are loosely arranged or have a fine finish. This approach is particularly suitable for components with large or complex surface areas.

The choice of the drying method therefore depends on the specific needs of the production process and the materials involved.

Firbimatic stands out for the implementation of advanced and tailor-made solutions, contributing to efficiency and quality in industrial drying processes.

Discover our machines for metal components cleaning and contact us for more information!

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.