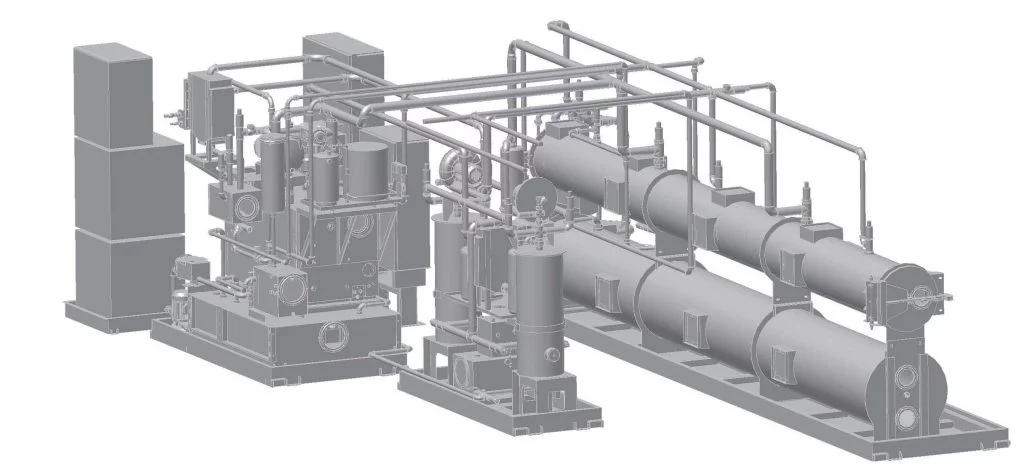

The wide range of metal and industrial component cleaning machines proposed by Firbimatic consists of standard units or custom-made systems to meet specific customer requirements.

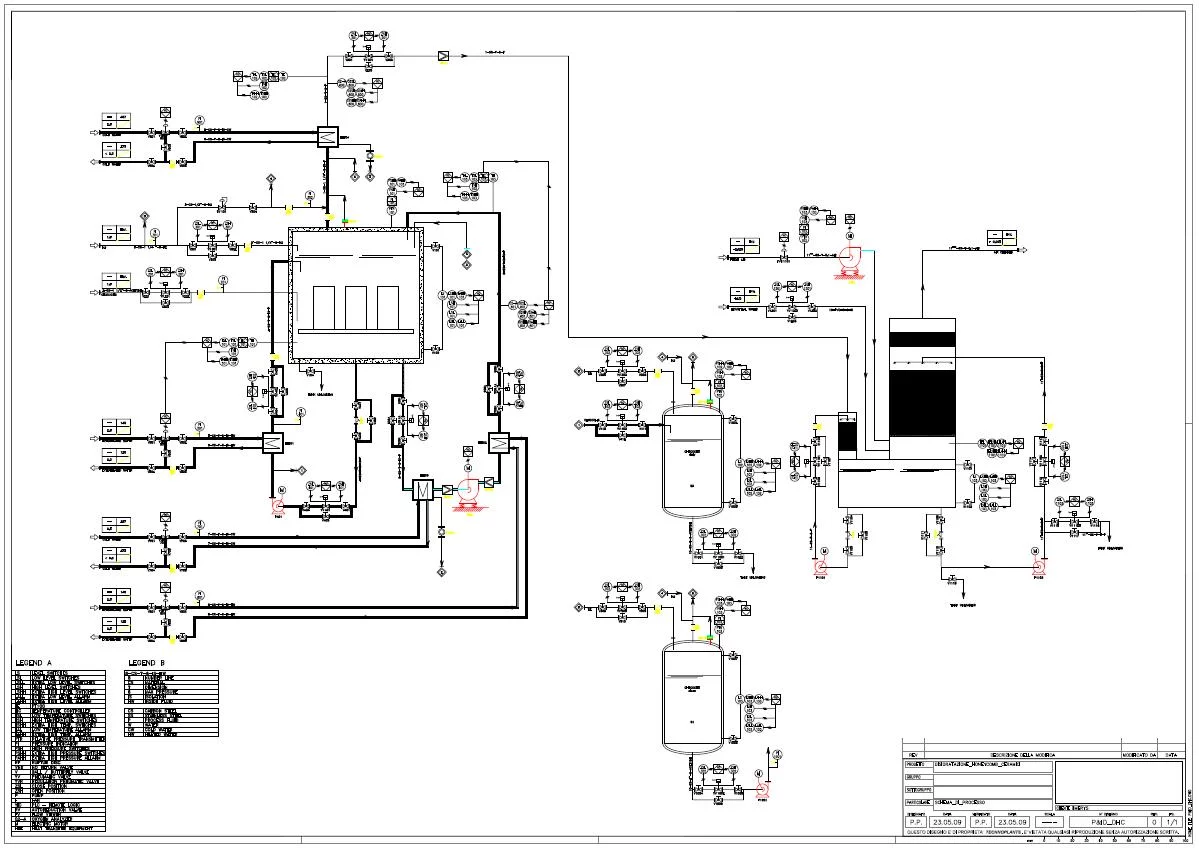

The proposed solutions allow the precise identifications of the most appropriate cleaning cycle based on the type of the component to be treated and based on the type of pollutant present.

Our range of cleaning machines consists of both models suitable for treating light and delicate precision components, as well as customized solutions that are employed in the cleaning of larger or more specific parts, for which a thorough and consistent level of cleanliness is required over time.

The production of Firbimatic Metal Cleaning Division's cleaning systems is divided between standard machines, having codified features and repeated schemes already realized, and other systems which are absolutely customized, to meet specific needs of individual customers, (both in terms of the size of the cleaning chamber and of the technological and process aspects of the cleaning machine to be designed).

The above is possible thanks to a top-notch Technical Department that relies on twenty qualified designers who know how to take advantage of their organization and of the high technology of company machine tools.

Our in-house metal-works factory performs the complete cycle of machining, to meet, in a short time, the needs for practical realization of extremely complex and high-tech cleaning systems.

Quality and precision are the utmost requirements of the production process, which includes both the construction of prototypes and the complete supply of all key components of the machine, all made of stainless steel, complete with surface treatments and painting.

Firbimatic relies on the cooperation of qualified external companies for the complementary turning, milling, boring, heat and galvanic treatments, painting, and surface finishing operations.

While the use of combined technology ensures high productivity for complex parts and enables operations to be carried out quickly and with great precision.

We dispose of a state-of-the-art laser cutting equipment, fed by the automatic sheet metal warehouse. We can process common steel sheets of max 20 mm thickness and stainless steel of max 25 mm thickness, which allows us to manufacture completely in-house even special non standard equipment.

We also have welding stations and robotic islands. The competence of the operators in the welding department is certified by the "BUREAU VERITAS" body and by Consultants holding "IWT - International Welding Technologist" qualification. Specific checks on welds can also be carried out at specialized external agencies or companies at the request of our customers.

The high quality standards are achieved mainly due to the great experience of the staff of the assembly and testing department, who have been with us for a long time and have followed the evolution of our metal washing plants since the foundation of our division fifteen years ago.

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.