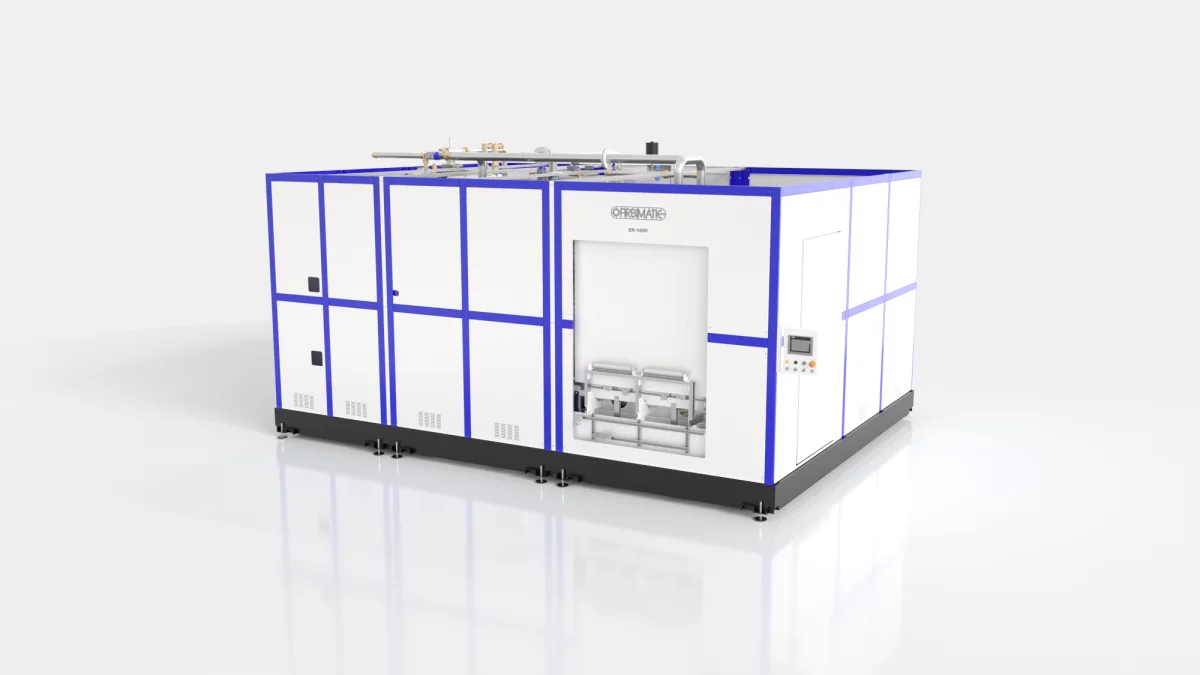

Originated from our deep experience in the industrial activity and also thanks to the gratifying successes that has followed our specialization in the cleaning of precision, automotive, aerospace and engineering components, our hermetically sealed degreasing machines are capable to perform a cleaning and drying treatment cycle under high vacuum level.

Our cleaning systems for metal components are designed to use different types of solvents in absolute safety.

The prior degassing of the solvent, performed initially for safety reasons, continues during the full immersion phase, ensures absolute absence of air bubbles and so the penetration and homogeneity of the dipping bath.

Through a multi-stage washing process, our washing systems can be optimally adapted to the various component cleaning needs. A typical cycle sequence is as follows:

The washing phases can be flexibly varied and parameterized and saved in the Siemens PLC programs.

At the end of the cycle, thanks to the drying stage with vacuum values less than 1-3 mBar, parts come out completely deodorized and without any solvent residue that can contaminate the work environment.

The solid particles of dirt, such as dust, metal chips and inorganic salts, are effectively removed by the mechanical action of the cleaning cycle combined with the selected movement of the basket.

Any layers of burned oil and additional contaminated solids deposited on the component (eg: Oxides and lapping and polishing pastes) require instead the action of ultrasonics that can be installed on request in the majority of our closed-circuit systems.

Distillation process for solvent machinesThe distillation process, vital function of solvent machines, consists of two distinct phases which allow an almost total separation between solvent and oils and it is distinguished by a negligible presence of solvent in the distillation residues.

In particular, the continuous distillation of the solvent (main phase of distillation) is alternated to the phase of Boil down of the still residues. This boil-down phase is made typically at the end of the day in the main distiller (or, if the option is present, through the secondary distiller, in this case also in a continuous process).

Boil down of oil sludge has the purpose of reducing the solvent content to values <1-2% of the sludge, which are then automatically ejected in a timed phase (under temperature control).

The operator NEVER comes in contact with the solvent since all the management operations of sludge of distillation and the cleaning of filters take place automatically.

Solvent cleaning systems have a negligible consumption of only a few liters per year; however, it is necessary to comply with the following conditions of use:

Our technical dept. will know how to present each customer the most suitable customized proposal suitable for his or her needs. We will appropriately evaluate specific cleaning problems and present the most suitable solvent system configuration to ensure the best cleaning result.

Vuoi maggiori informazioni su questo prodotto/servizio?

Compila il modulo senza impegno

+39 051 6814604 (Fax)

FIRBIMATIC s.p.a a S.U. • Codice Fiscale e Partita Iva 01892941202 • R.E.A. Bo n. 396747 • Iscrizione al Registro Imprese di Bologna n. 01892941202 • Capitale sociale 3.650.400,00 Euro i.v. • Privacy • Sitemap • This site is protected by Google reCAPTCHA v3, Google's Privacy Policy and Terms of Service.

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.