In the medical world CLEANLINESS is crucial.

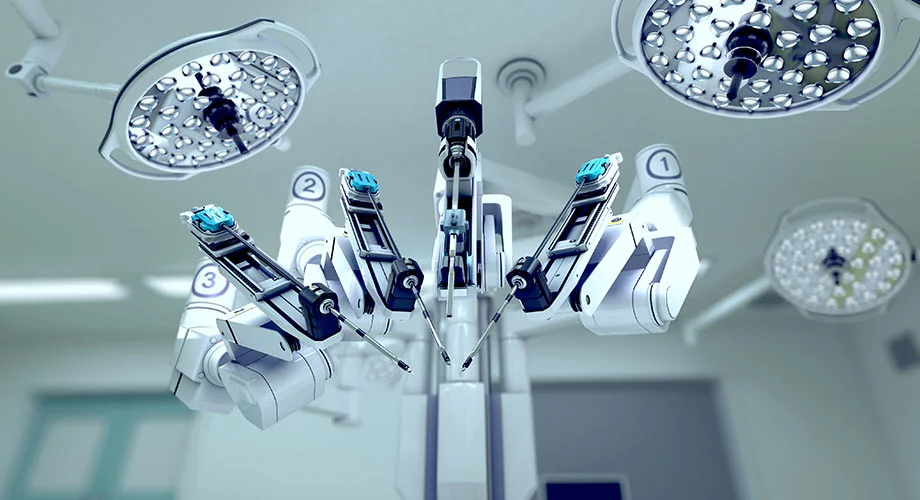

Any metal instrument or component whether they are disposable, reusable or implantable must be cleaned and sterilized to prevent complications.

Medical device OEMs must provide proof their products are clean and meet all specifications of the regulatory agency of the country.

The production process must ensure the complete absence of surface contamination, thus preventing infections that are critical to the health of patients.

Quality and reliability are increasingly required as well as continuous improvements in the cleaning of the components used daily in numerous medical activities.

The final product must comply with specifications and manufacturing cleaning methods must meet environmental, health and safety concerns.

Biocompatibility is the set of properties that make a material or a device compatible with the human body.

Most production parts are cleaned before being delivered. In an industry where production time, volume and quality are critical, it is important that medical parts otbain such results.

Facility managers, Firbimatic included, are seeking to become more familiar with aqueous and solvent cleaning solutions so as to identify their respective strenghts and weakenesses.

Soils and materials are constantly changing, so it is very important to stay up to date on the innovative technologies .

During the evaluation, washing systems that use aqueous solutions and those that use solvents are compared.

Todays the current cleanliness specifications indicate that most metal parts intended for the medical sector cannot have any contaminant or rinse water residue thus pushing the interest of many companies towards solvent-based washing systems.

Firbimatic systems for washing solvent-based metal components:

Many medical devices and components are produced using materials that resist corrosion, are compatible with the body and have a long-term reliability/endurance such as titanium and stainless steel.

These metals are preferred to others to shape the final device.

For example, the metal thickness for pacemaker cases is very thin for weight reduction and size.

These thin-walled materials need a lubricant to facilitate the molding or forming processes that will alleviate any abrasion and wear and improve the elasticity of the metal itself.

The dirt residues produced during these processes are not easily removed with water washing systems: it is the solvent that generally is superior thanks to its greater cleaning qualities.

Furthermore, the recycled solvent can be re-used after being adequately filtered.

We suggest that you read the article LEGHE LEGGERE LAVORATE case to discover the solutions proposed by Firbimatic to the cleaning needs of medical devices.

The type of solvent used in the various degreasing machines now is not the same solvent used few years ago.

The concepts of “old” and “new” solvents also arise as a result of changes at the government level.

A lot of solvents are being phased out or becoming more restricted by the local Authorities. Many solvents are moving toward more environmentally green cleaning processes and moving away from halogenated solvents.

We suggest that you read the article VDA 19 and ISO 16232: Quality of metal cleaning systems to know more about the main aspects of Quality in metal cleaning systems.

A widely shared and apical solution in the Firbimatic panorama is represented by modified alcohol, a water-free solvent with excellent cleaning power designed to ensure high performance in closed vacuum degreasers.

To follow are the main advantages:

Another point in favor of this type of solution is represented by the lower energy consumption and the low VOC levels.

Closed vacuum degreasers represent the future when it comes to solvents.

The operators , as well as the ambient area, are isolated from the cleaning process which is performed in a sealed vacuum chamber.

These systems offer an excellent cleaning choice for a wide range of contaminants .

Finally, there are numerous features that allow highly effective washing cycles on precision components, such as :

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.